Loading...

For Production Including Compounding, Milling, Weighing and Aseptic Testing

Bio/Pharmaceutical Flexible Film Isolators & Accessories

Durable ● Economical

You Should Consider the Cost Saving Advantages of Flexible Film Barrier and/or Containment Isolators for Bio/Pharmaceutical Production.

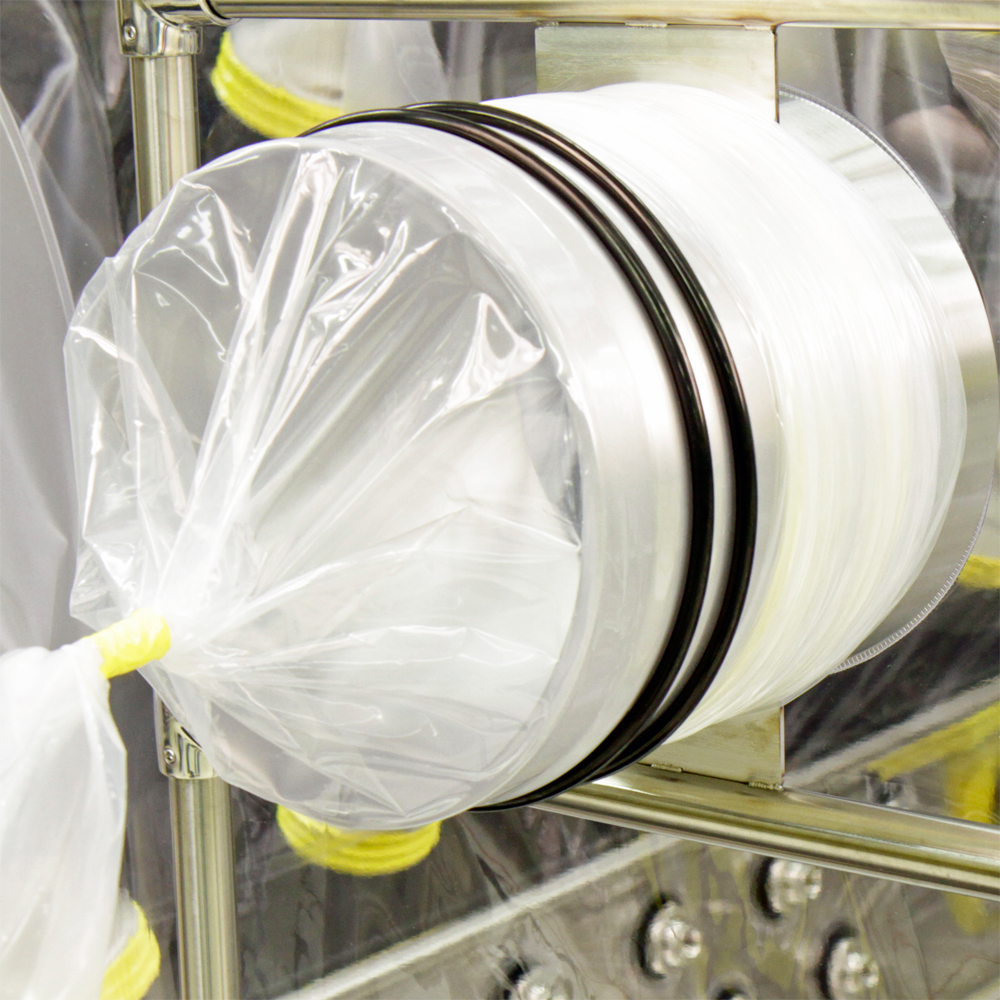

Learn morePharma Isolator with HEPA Inlet and Outlet

The example shown includes: two bag in bag out ports, internal water wash down spraying system, floor drain, gas-tight zipper, internal power outlets and tube ports for running material into and out of the isolator.

Learn moreThe flexible film (softwall) chambers are completely enclosed. (This is not a laminar airflow design.)

Positive Pressure - Designed to provide a completely controlled production environment so chronic studies do not have to be started over due to contamination of control or test specimens.

Learn moreThe flexible film (softwall) chambers are completely enclosed.

Negative Pressure - Designed to Protect Workers and Surrounding Environment.

Learn moreTo Maintain a Controlled Environment

Transfer ports, bag-out ports, HEPA filters , gauges and emergency back-up supply.

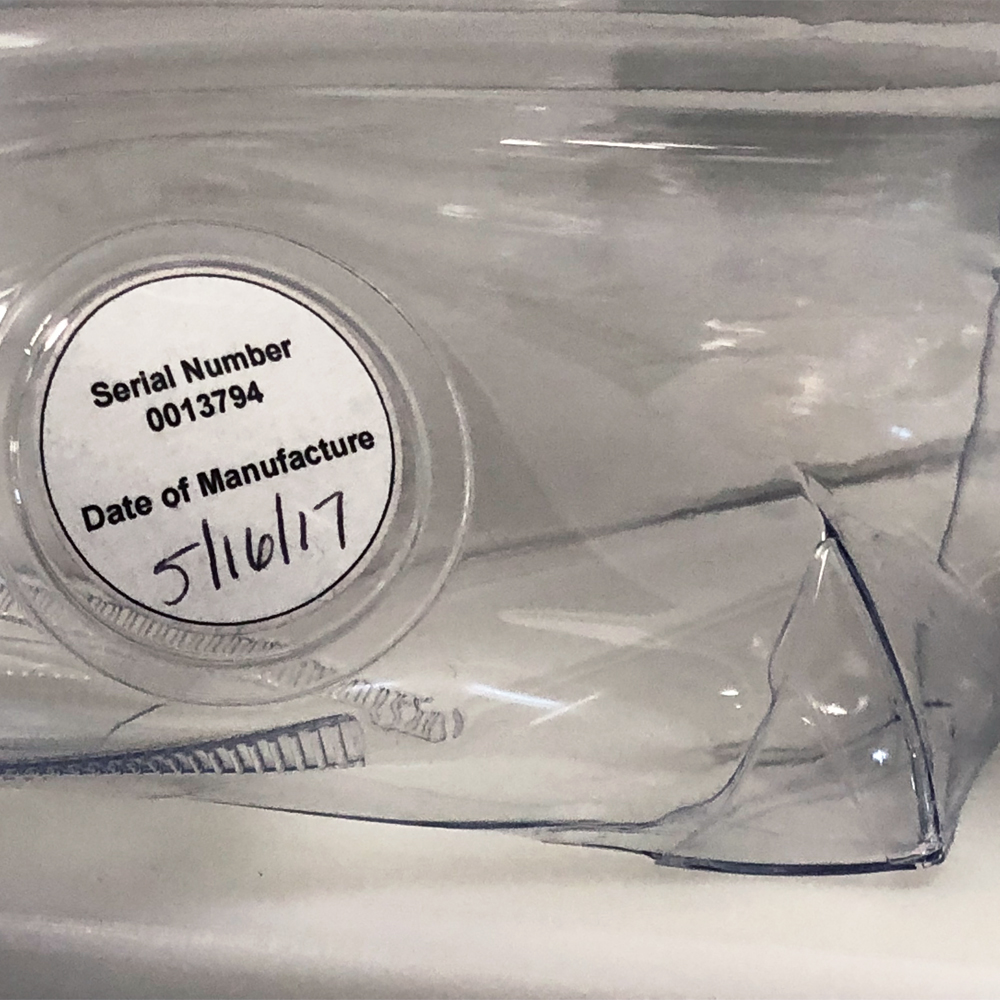

Learn moreConsider single-use flexible film canopies to save time and avoid contamination.

20 mil vinyl or polyurethane canopies constructed using CBC's unique lap seam seal process.

Learn moreSend Us a Message

Protecting Both Research and Researchers

Animal Research Gnotobiotic Isolators | Bio/Pharmaceutical Barrier & Containment Isolators

608.273.9661

●

810 Stewart Street, Madison, Wisconsin 53713

●

info@cbclean.com

© 2011-2022 Class Biologically Clean, Ltd. - Madison, Wisconsin - All rights reserved

® CBC is a Registered Trademark of Class Biologically Clean, Ltd.