Loading...

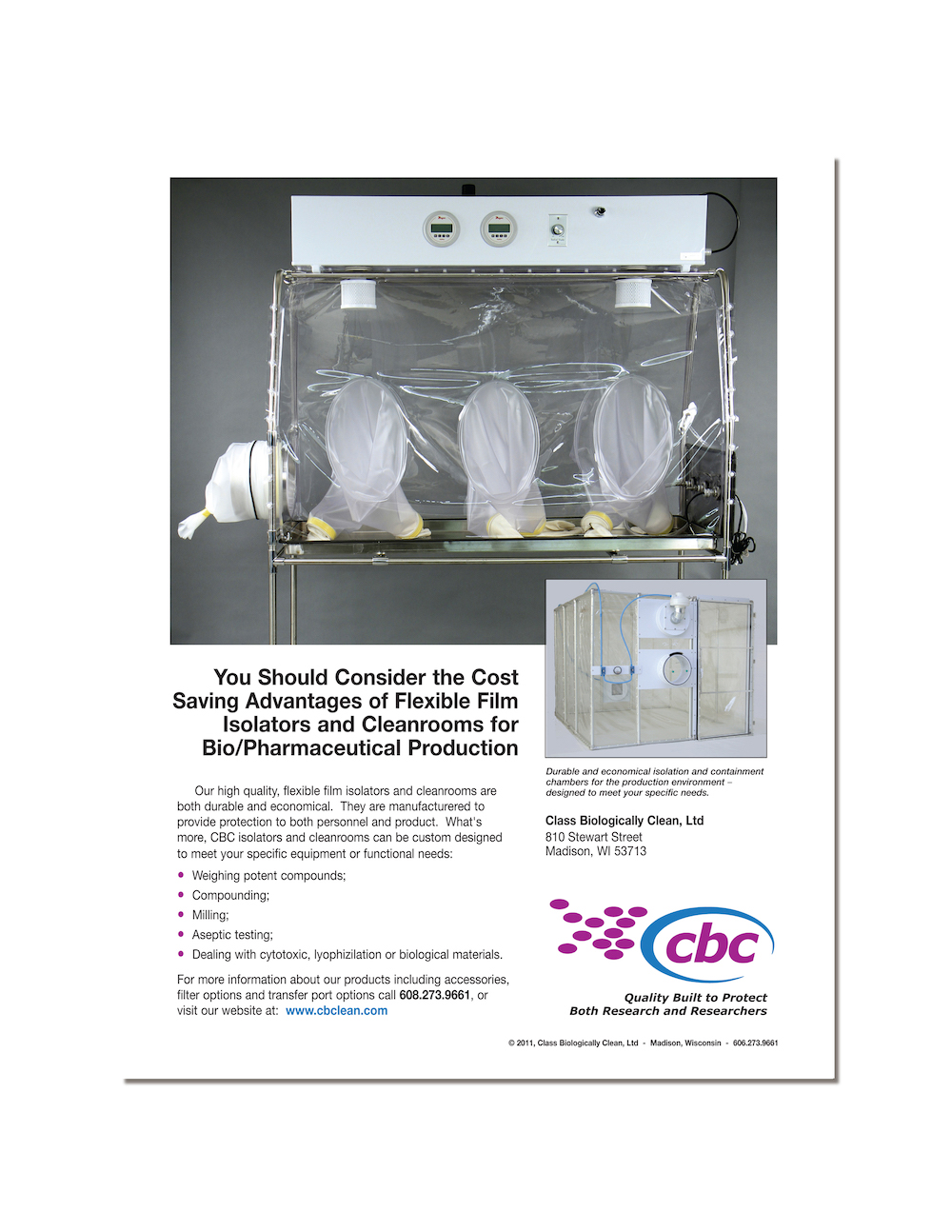

Barrier and/or Containment Isolators for Bio/Pharmaceutical Production Including Compounding, Milling, Weighing and Aseptic Testing.

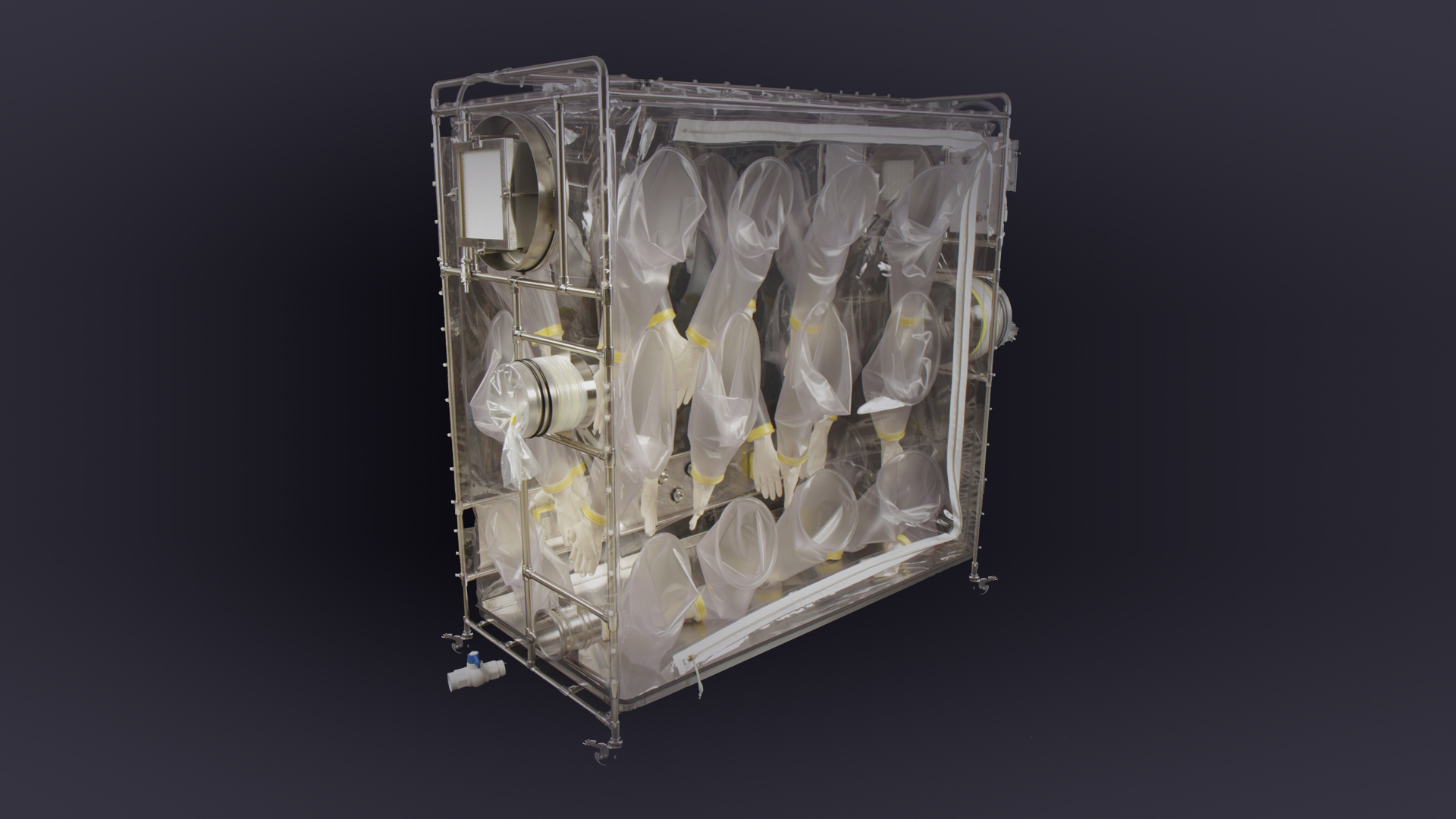

Flexible-Film Isolators

Flexible-Film Isolators

Flexible film barrier and/or containment isolators for Bio/Pharmaceutical Production Including Compounding, Milling, Weighing and Aseptic Testing

Each system is manufactured to meet your specifications. Positive pressure or negative pressure.

Turbulent Flow Isolators

Positive Pressure ● Negative Pressure

For Bio/Pharmaceutical production including compounding, milling, weighing and aseptic testing. Note: Each system is manufactured to meet your specific requirements.

Turbulent Flow, Flexible Film Isolator:

CBC's turbulent flow, flexible film isolators are more practical and more economical then using expensive stainless steel, laminar flow isolators for many bio/pharma research and test production tasks. We custom design isolators to meet unique space and research and production requirements at a price that won't break your budget.

You Should Consider the Cost Saving Advantages of Flexible Film Barrier and/or Containment Isolators for Bio/Pharmaceutical Production

Our high quality, flexible film barrier and containment isolators are both durable and economical. They are manufactured to provide protection to both personnel and product. What's more, CBC isolators can be custom designed to meet your specific equipment or functional needs:

- Weighing potent compounds,

- Compounding,

- Milling,

- Aseptic testing,

- Dealing with cytotoxic, lyophizilation or biological materials.

Also, if cleaning and decontamination of your isolator is too time consuming, our canopies are very economical and can easily just be replaced!

The CBC Bio/Pharmaceutical Isolator System:

- Stainless steel 316 framework.

- PVC or polyurethane film.

- Positive or negative pressure.

- Turbulent airflow.

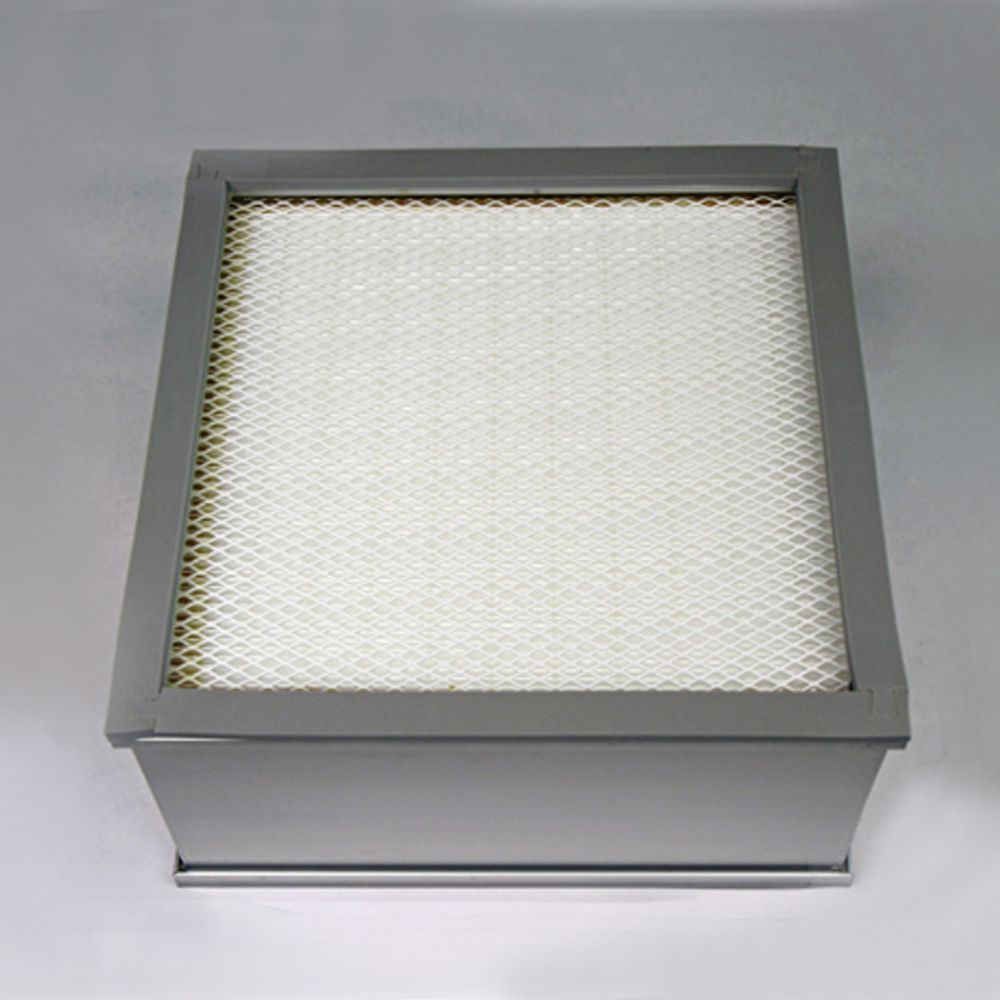

- HEPA filtered inlet air.

- Single or double HEPA filtered exhaust air.

- Several transfer port styles.

- Mobile systems with two-way locking casters.

Accessories:

- Pressure gages for monitoring pressure.

- Bag out filter housing.

- Internal electrical power and water.

- Internal contained drain system.

- VHP or CLO2 sterilizing attachments.

- Variable frequency drive motor (VFD) speed controller. The VFD monitors the pressure within the isolator and automatically will adjust the speed (increase or decrease) to keep the pressure within a stated range.

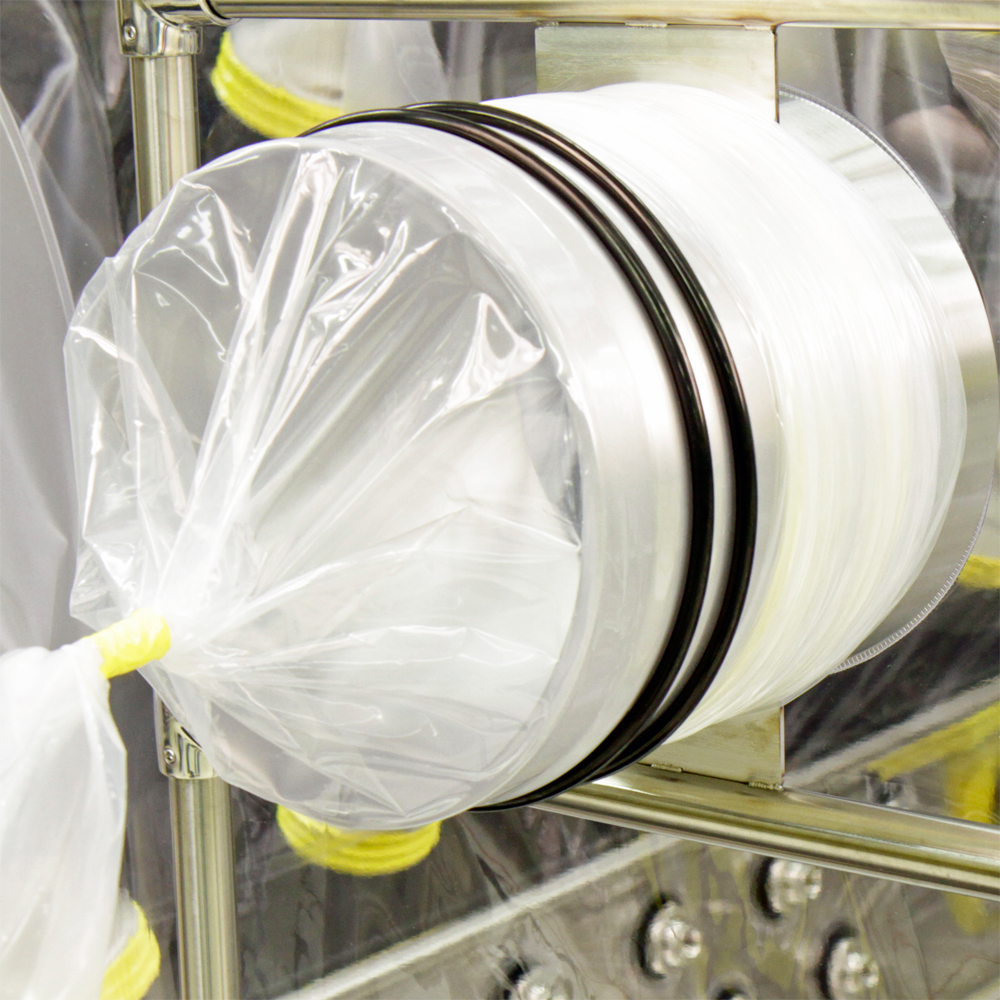

Filter and Transfer Port Options:

Each flexible, barrier isolator system comes with a HEPA filter

on the inlet and exhaust. An attachment can be added to the exhaust filter housing to allow for exhausting into the building's

exhaust system. Alternatively, a second HEPA filter can be added to the exhaust system to allow venting back into the room. ULPA filters are also available.

The transfer port systems come in stainless steel, acrylic, or polypropylene. The design can be the conventional system with two (2) removable vinyl caps,

a bag in and bag out system; or a rapid transfer port system.

NOTE: Our flexible barrier and/or containment chambers can be radiated if required!

How to Proceed::

If you are not sure where to begin or what you need, we can help you through the planning process including DQ, IQ, OQ and PQ.

Download Printable Flyer

Download a printable flyer about CBC flexible film barrier and/or containment isolators for bio/pharmaceutical production.

Download Printable PDF

The CBC Difference

The CBC difference includes our original lap-seam sealing process and the use of 20 mil. polyurethane material that is almost indestructible and helps ensure against contamination due to accidental puncture or tear.

CBC uses a highly durable "lap seam" seal for the majority of our seams, and an even superior "cut/weld/strip seam" seal for high risk areas. Because your reputation, research or production should not risk being compromised! (See, "Pull Test" and "Puncture Demonstration" videos below.)

The CBC Lap-Seal Seam "Pull" Test

Single Seam Seal vs. CBC Lap Seal Seam Read more

Because your reputation, research or production should not risk being compromised!

20 mil. Polyurethane Puncture Demonstration

CBC's 20 mil. polyurethane material is almost indestructible and helps ensure against contamination due to accidental puncture or tear. Read more

Because your reputation, research or production should not risk being compromised!

Custom Production Isolator

With gloves and gas-tight zipper door. Read more

For Bio/Pharmaceutical Production.

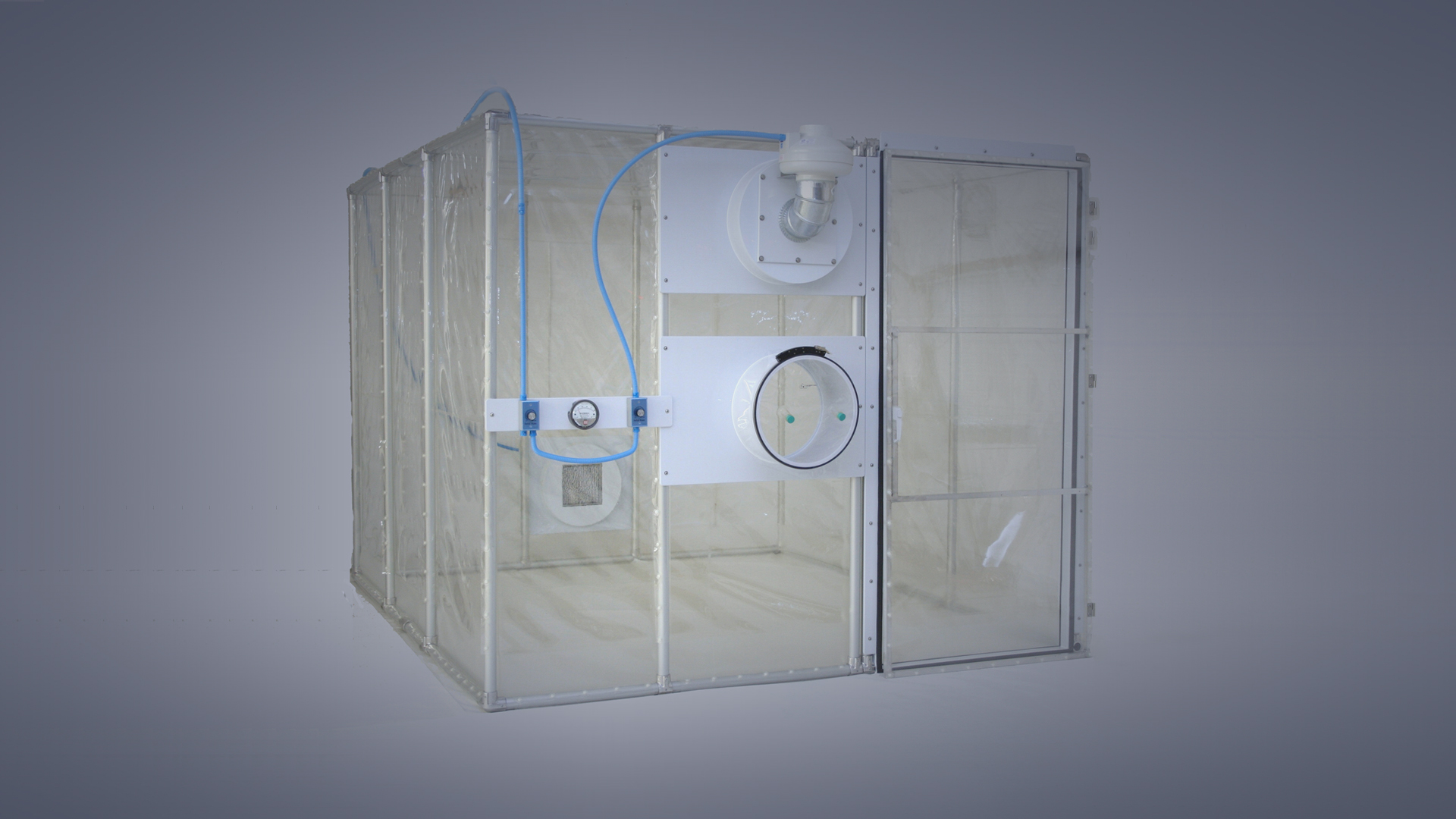

Positive Pressure, Flexible-Film (Softwall), Cleanrooms

The flexible film (softwall) chambers are completely enclosed. (This is not a laminar airflow design.). CBC softwall clean rooms are available in 4 standard sizes and are relatively inexpensive when compared to other systems. Read more

For Bio/Pharmaceutical Production.

Decontamination Chambers

Decontaminate equipment used in research and production. Read more

For small items such as scales and microscopes.

Negative Pressure, Flexible-Film (Softwall), Containment Units

Pictured above is a negative pressure, flexible film (softwall) containment unit that is designed to be a necropsy room, with enough space for a necropsy table, waterline, discharge collection and pass in/out transfer port (restricted access barrier unit). Read more

Designed to Protect Workers and Surrounding Environment!

Accessories and Components:

Pictured above is a custom negative pressure, flexible film, gas-tight zipper production isolator

Custom Production Pharma Isolator with HEPA Inlet and Outlet

Includes: two bag in bag out ports, internal water wash down spraying system, floor drain, gas-tight zipper, internal power outlets and tube ports for running material into and out of the isolator.

Learn more

Single Use Disposable Canopy/Chamber Saves Valuable Time and Minimizes Opportunity of Product Contamination.

CBC canopies are very economical and can easily just be replaced.

Avoids the time consuming tasks of cleaning and decontamination of your isolator canopy.

Learn moreSend Us a Message

Protecting Both Research and Researchers

Animal Research Gnotobiotic Isolators | Bio/Pharmaceutical Barrier & Containment Isolators

608.273.9661

●

810 Stewart Street, Madison, Wisconsin 53713

●

info@cbclean.com

© 2011-2022 Class Biologically Clean, Ltd. - Madison, Wisconsin - All rights reserved

® CBC is a Registered Trademark of Class Biologically Clean, Ltd.